As a contractor, my two least favorite questions are “How long will it take?” and “Are You Done Yet?” Perhaps it is because it reminds me of the long trips in the car when my children were young and they asked the infamous question “Are we there yet?”

To answer the question “how long will it take,” there is no clear cut answer. No two jobs are alike. Construction phases take varying amounts of time.

The outline below is a general guideline of what to expect during a home remodeling experience. One thing to remember is that you may not see someone at your site daily when you do a home remodeling project. Scheduling, weather, inspections, and material availability all play a part in how long your project takes to complete.

HOME REMODELING PROCESS / STEPS

If you read through all of the following steps, you will see that there are many moving parts that must be coordinated to complete a project. Leading Edge Homes, Inc. tries to ensure that your home improvement project moves along as quickly as possible, but will never sacrifice quality for speed.

Please note, not all of the following steps are required for each type of job. Each step is prefaced with an “A” for an Addition and “R” for a Remodeling / Renovation project.

A — PRELIMINARY SOIL TESTS / SURVEYS

AR — REROUTING WIRES OR PLUMBING

Rerouting of overhead electric, cable TV, and phone service, and sewer and water supply lines if necessary.

AR — DEMOLITION

Any existing structures (roof overhangs, screen rooms, existing concrete, etc.) in the way of the addition are removed. Land is cleared by machinery if site conditions allow, otherwise it is cleared by hand.

For an interior remodel, the cabinets, walls, floor coverings, and fixtures in the work area are removed. This creates lots of dust. Make sure any objects that could not be removed are protected.

Debris is placed in a designated area or in the provided trash receptacle. Leading Edge Homes, tries to clean up the site daily, however, at times piles of debris are visible.

A — EXCAVATION AND SETTING FORMS

The addition area plus at least 3 feet beyond are cleared down to suitable soil.

Fill dirt is delivered to the addition area and compacted. Please do not remove any of this dirt. It is needed to create the house pad.

Footers are dug around the addition perimeter and forms are placed into the dirt.

These forms are set in place with precision instruments, and a survey will be taken with them in place. Do not move or alter them in any way. Should you accidentally step on or disturb one of these forms, please contact the office immediately so the forms can be rechecked for accuracy before the concrete pour.

A soil density test is conducted.

A form board survey is performed.

A — UNDERGROUND UTILITIES

The underground plumbing, electric, and air conditioning pipes are placed in what becomes the slab. Do not remove or change the position of any of these items. They have been placed in the precise location in which they are needed.

Separate inspections for each of these trades is performed. Inspections may not occur on the same day. All trades must pass inspection before work can proceed.

A — POISON THE SOIL

This is the first of two sprayings to prevent termites. Do not touch the soil! It is hazardous to your health.

A — SLAB FORMATION COMPLETION

Plastic, steel (it may be rusted, but that does not effect the strength of the slab), and recess forms are put into place.

Another inspection is performed.

A — POUR THE CONCRETE

Once the pad is formed and passes all inspections, the slab will be poured. This is a difficult date to schedule. It is subject to weather conditions (on the date of the pour and on prior days), equipment availability, and the concrete finishing crew’s schedule.

Your patience is appreciated. We are as anxious as you to complete this phase. If you can’t resist, please wait at least 24 hours after the concrete finishers have left before walking on the new concrete.

Some concrete may squeeze out from under or around the forms. This is a normal condition.

Loads of concrete may vary in color. This is a normal condition and does not affect performance.

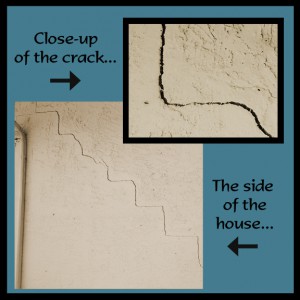

Cracking may occur during the first 90 days of curing, and later during the first year. Steel reinforcement has been installed in the slab to reduce the separation of the concrete when it cracks. (The concrete will be specially prepared if tile is to be installed on it.)

Sudden inclement weather conditions may require protecting wet concrete with a temporary plastic covering. This may result in an alteration of the finished appearance of the concrete surface. Do not be concerned. This does not affect the concrete’s performance.

A — BUILD EXTERIOR WALLS AND ROOF

Wood / Steel Framed Construction

The exterior walls are framed with wood and / or steel.

The roof trusses are set, sheathing is attached to the trusses and exterior walls, and the fascia is installed.

It is time for another inspection.

Block / Masonry Construction

The exterior walls are built with masonry block.

The column and beam steel is installed.

The tie beam is formed, where and if needed.

It is time for another inspection.

Wood scraps are fastened over any column clean out holes.

Concrete is poured into the tie beam and columns.

Note: This concrete is a special mix and appears to be watery! Do not be concerned. Its formulation causes it to be extremely strong when dry.

The roof trusses are set, sheathing is attached to the trusses, and fascia is installed.

It is time for another inspection.

A — ROOF COVERING

The roof is dried in. Roofing underlayment is attached to the sheathing, and metal drip edge, valley, and “L” flashing is installed.

Skylights (if any) are installed.

It is time for another inspection.

If the final roof covering is tile, more roofing underlayment may be installed, and the tile is loaded on the roof. Otherwise, the final roofing material is installed on the roof.

A R — INTERIOR FRAMING

The window bucks and windows are installed.

The exterior door bucks and doors are installed.

Interior walls are framed and block walls are firred as necessary.

You can now see your room(s). They may appear smaller than you expected, but will look larger once the drywall is installed.

The rough air conditioning (duct work), plumbing (including tubs), and electric are installed.

It is time for more inspections.

A — PREPARING THE HOUSE EXTERIOR

Wire lath is installed over exterior sheathing, and in the soffits.

Scaffolding may be present on your job site. DO NOT allow children to play on it.

Hurricane tracks are installed (if they are embedded in the stucco).

It is time for another inspection.

The exterior is painted, then roof tile, if applicable, is installed.

A R — INSULATION

Insulation is installed in the walls and ceilings.

It is time for another inspection.

A R — DRYWALL

Drywall is fastened to walls and ceilings.

In most municipalities, it is time for another inspection.

The walls and ceilings are finished. This multi-step process is effected by humidity, and requires varying amounts of drying time.

Wall and ceilings are spray textured, if applicable.

A R — INTERIOR FINISHING TOUCHES

Interior doors are hung, and pull down stairways are installed.

Cabinets are installed.

Interior base and case moldings are installed.

Tile is installed on floors and walls, if and where applicable.

The interior is painted.

Shelving, mirrors, countertops, and tub skirts are installed.

The air conditioning equipment and grills are installed.

The final plumbing fixtures and faucets are installed.

The electric switches, outlets and fixtures are installed.

It is time for inspection of all the trades.

A — EXTERIOR FINISHING

Hurricane hardware is installed.

The flatwork (sidewalks, patio areas, etc.) is formed. Soil in areas under roof are sprayed to prevent termites. Do not touch the soil! It is hazardous to your health.

Reinforcing steel may, or may not, be placed in the flatwork area.

The flat work is inspected.

The concrete is poured. This is a difficult date to schedule, due to weather conditions (on the date of the pour and prior days), equipment availability, and the concrete finishing crew’s schedule.

Your patience is appreciated.

You may walk on the new concrete 24 hours after the pour. Do not drive on a new concrete driveway for at least one week.

Loads of concrete may vary in color, and will NOT be the same color as existing sidewalk, driveway, or patio areas. There is no way to control the color variations of concrete.

The final vertical spray for termites is performed.

Any sod replacement and sprinkler repair specified is performed.

A R — THE PROJECT IS ALMOST DONE

Screens are installed in any windows. The dumpster and portable toilet will be removed from your site.

The FINAL BUILDING INSPECTION is performed.

The carpeting is installed. This is done after the final inspection because we want no one to walk on your new carpet but you!

A R — ENJOY YOUR FINISHED PROJECT

Leading Edge Homes thanks you for your patience and hopes you enjoy the changes to your home.

If you are considering a home remodeling project or have been inspired by something you have seen on television and want to determine if it can be duplicated in your home, contact Leading Edge Homes, Inc. at 561-795-2551. We will give you a real, guaranteed price and our best guestimate of how long the project will take.